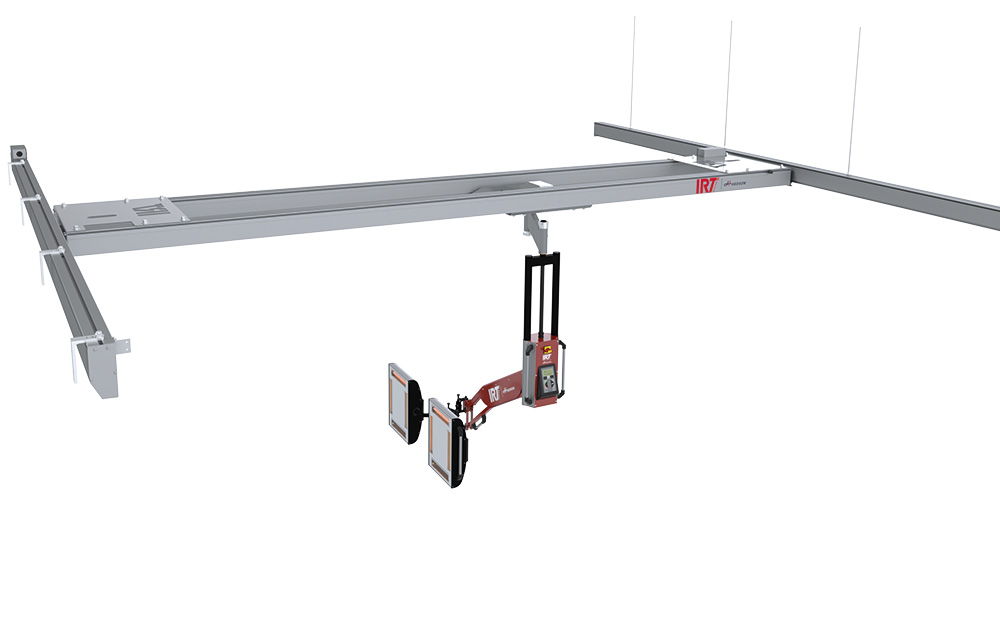

IRT Rail System IR Dryers

The dryer is equipped with advanced technology such as a temperature measurement, laser circle and ultrasonic distance sensor

IRT Rail System IR Dryers

Are easy to use and the curing time is reduced to a minimum

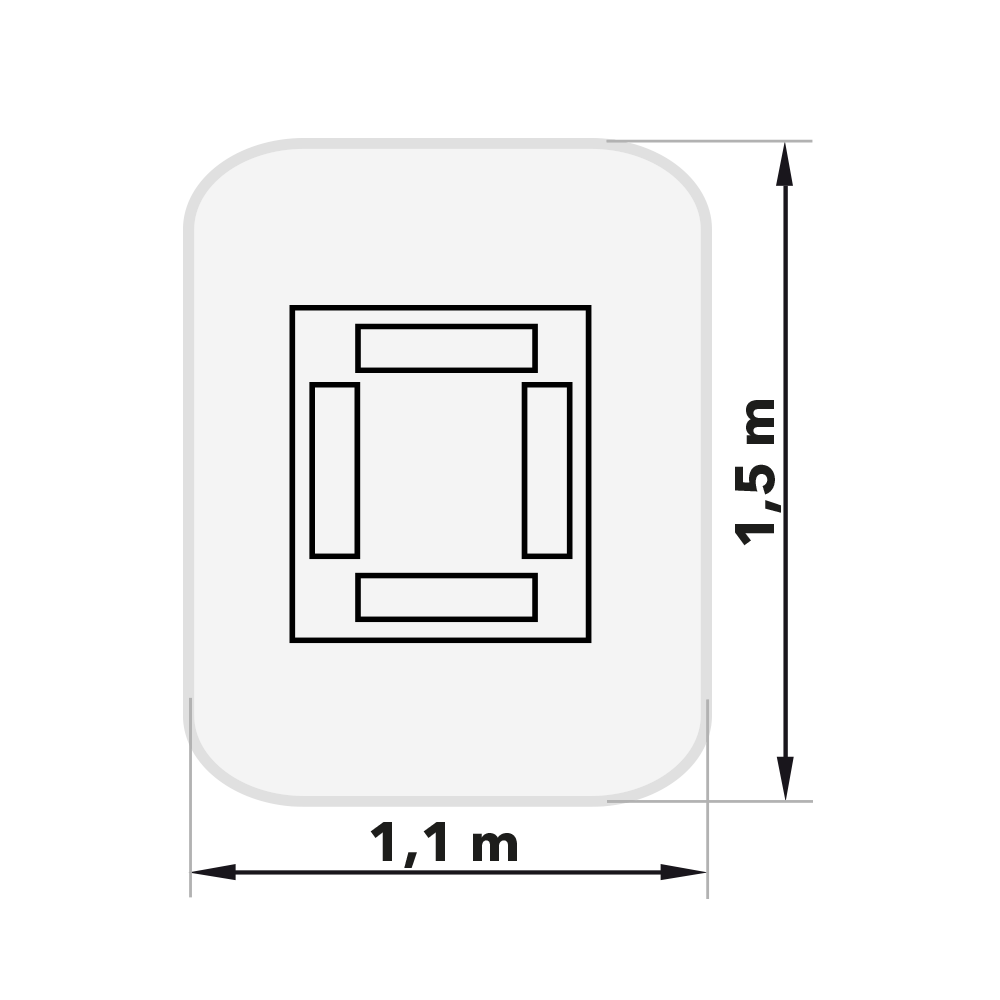

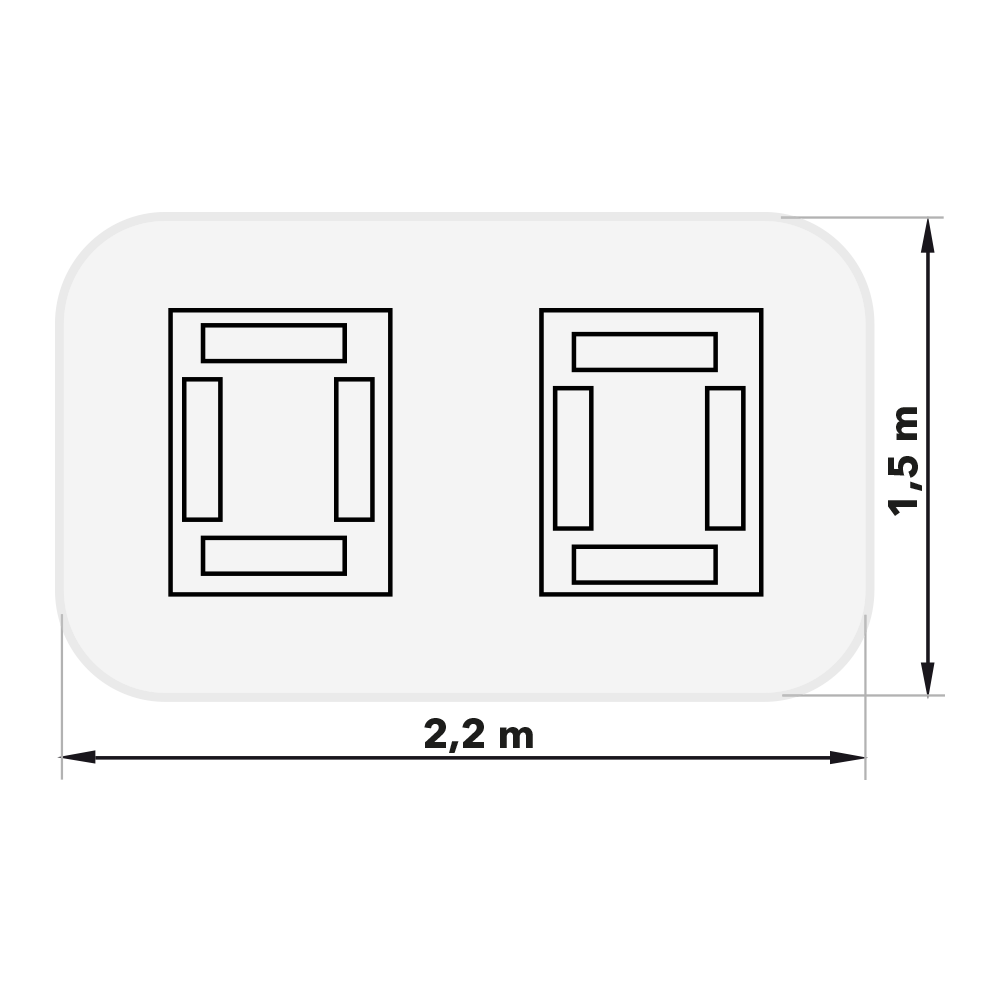

4-10 (1 cassette) & 4-20 (2 cassettes)

Advanced technology

Computerized curing process, 12 pre-set and 3 custom programs. The pyrometer ensures exact temperature control and the laser circle indicates where temperature measuring takes place - all to optimize the job result

Customization

Can be customized to suit all workshops for a optimized workflow and personalized needs. Reach and quickly manoeuvre the heater into the perfect curing position, reaching all parts of the vehicle

EFFICIENCY

These dryers are suspended in permanently installed rails and are easy gliding and self-balancing, both laterally and vertically in all directions. As the electric power supply is integrated in the rails, there are no loose cables dragging along the floor disrupting work and raking up dust

Equipped with user friendly advanced technology IRT 4-10 PcAuto by Hedson has the same features as IRT 4-1 and 4-2 PcAuto and are easy to use and the curing time is reduced to a minimum. The dryers are equipped with advanced technology such as a temperature measurement, laser circle and ultrasonic distance sensor. 18 different languages can easily be set.

One cassette at a distance of 600 mm, on black sheet metal

Equipped with user friendly advanced technology IRT 4-20 PcAuto by Hedson has the same features as IRT 4-1 and 4-2 PcAuto and are easy to use and the curing time is reduced to a minimum. The dryers are equipped with advanced technology such as a temperature measurement, laser circle and ultrasonic distance sensor. 18 different languages can easily be set.

Two cassette at a distance of 600 mm, on black sheet meta

IRT Rail System – Infrared Dryers

by Hedson

IRT Rail System – Infrared Dryers 4-10 PcAuto & 4-20 PcAuto

These dryers are suspended in permanently installed rails and is easy gliding and self-balancing, both laterally and vertically in all directions. As the electric power supply is integrated in the rails, there are no loose cables dragging along the floor disrupting work and raking up dust. Easy to use and the curing time is reduced to a minimum. The dryers are equipped with advanced technology such as a temperature measurement, laser circle and ultrasonic distance sensor. 18 different languages can easily be set.

Technical Specification

4-10 PcAuto

- 4-10 PcAuto - type 1

- Part.no. 800525

- 4-10 PcAuto - type 2

- Part.no. 800489

- 4-10 PcAuto - type 3

- Part.no. 800494

- Frequency

- 50-60 Hz

- Current - version 1

- 15 A

- Current - version 2, 3

- 9 A

- Output power

- 6 kW

- Fuse - version 1

- 16 A

- Fuse - version 2

- 10 A

- Fuse - version 3

- 20 A

- Voltage - version 1

- 200-230V 3Ph/PE

- Voltage - version 2

- 400V 3Ph/PE

- Voltage - version 3

- 440-480V 3Ph/PE

4-20 PcAuto

- 4-20 PcAuto - version 1

- Part.no. 800480

- 4-20 PcAuto - version 2

- Part.no. 800498

- 4-20 PcAuto - version 3

- Part.no. 800464

- 4-20 PcAuto - version 4

- Part.no. 800479

- Frequency

- 50-60 Hz

- Current - version 1, 2

- 30 A

- Current - version 3, 4

- 17 A

- Output power

- 12 kW

- Fuse - version 1, 2

- 32 A

- Fuse - version 3

- 16 A

- Fuse - version 4

- 20 A

- Voltage - version 1, 2

- 200-230V 3Ph/PE

- Voltage - version 3

- 400V 3Ph/PE

- Voltage - version 4

- 440-480V 3Ph/PE

Manual Operation Manual

Spare part list

As a Hedson Partner you can log-in to take part of our spare part lists. Log in…

If you are a Hedson Partner but don’t have access to the Partner Portal, please contact your Hedson contact person to get your account.

If you are an end-user, please contact your local reseller for more information.