IRT FlexiCure

Flexible

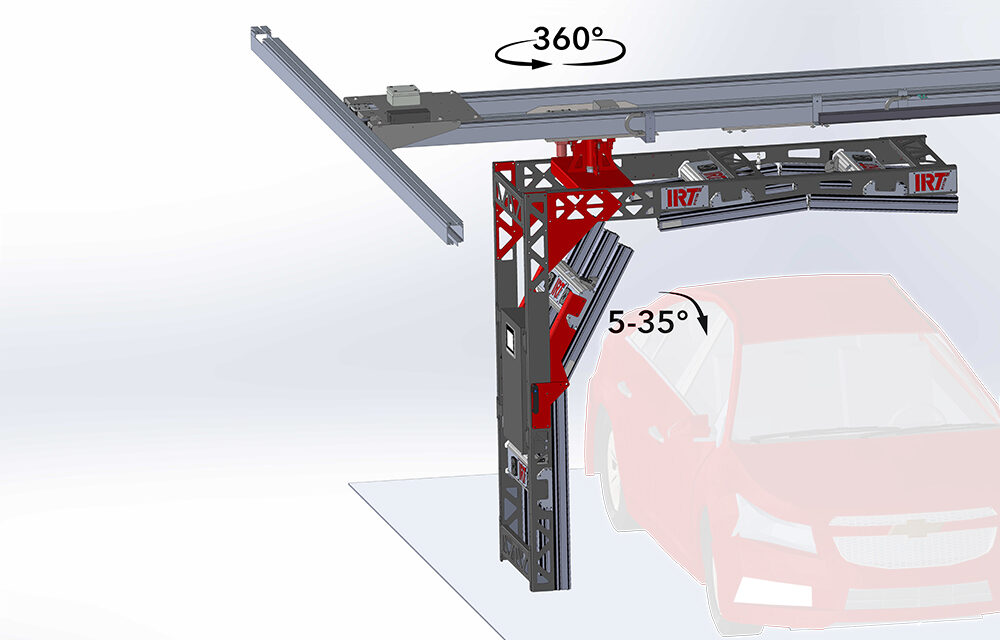

Accelerated curing in the prep area, both automatic and manual, static and dynamic. Tiltable zone for adjusted effect.

Cost effective process

Saves energy by only activating the necessary IR lamps using pyrometers and distance sensors. Complete flexibility with IRT Rails and tiltable zone.

Time saving in the prep area

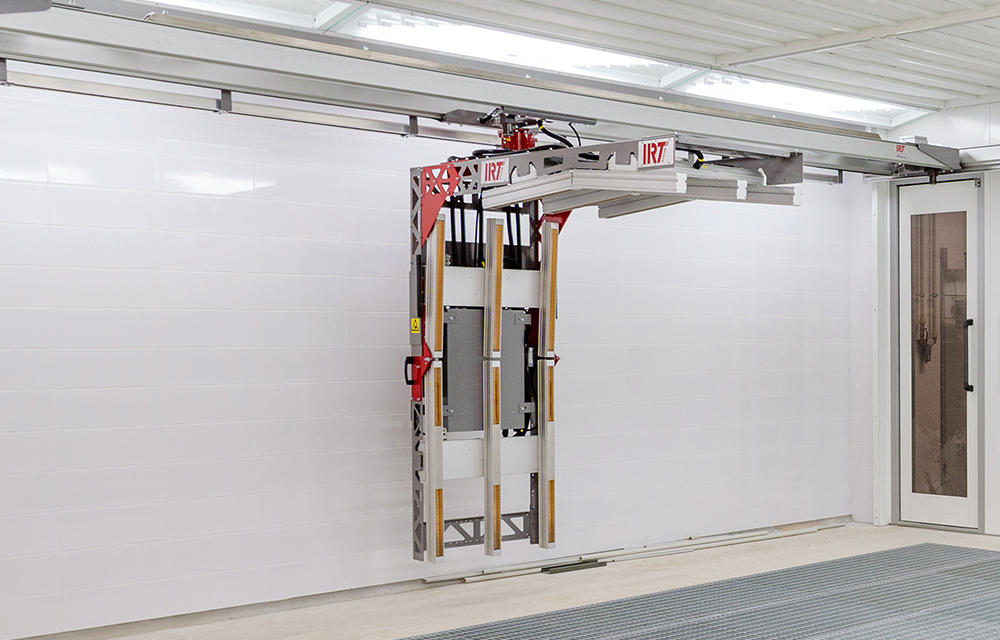

User-friendly IRT FlexiCure is installed in a standard IRT Rail System and accelerates curing of water- and solventbased base and clear coats.

IRT FlexiCure

by Hedson

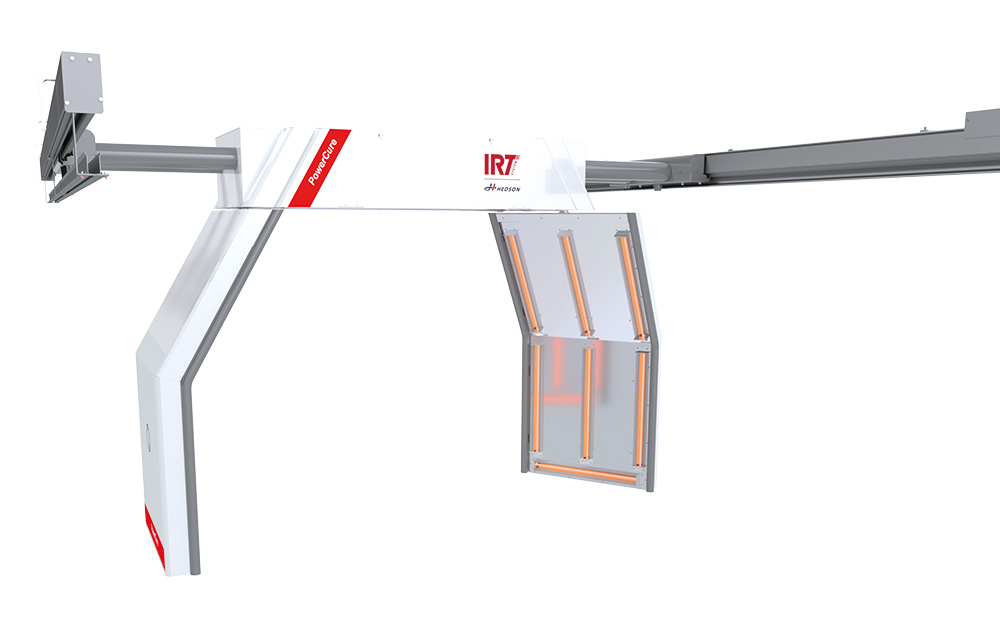

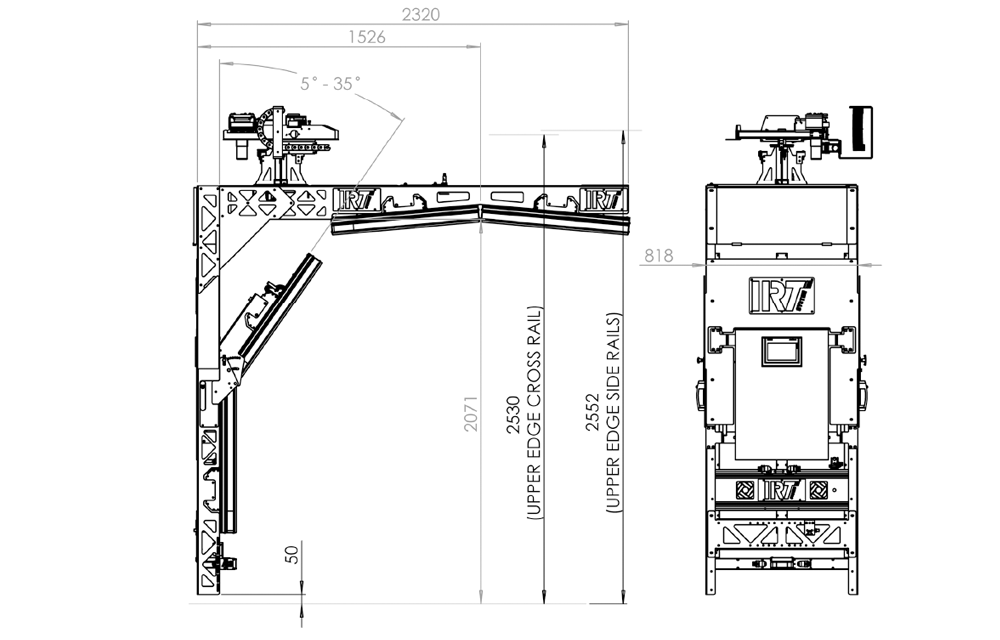

IRT FlexiCure with 4 curing zones

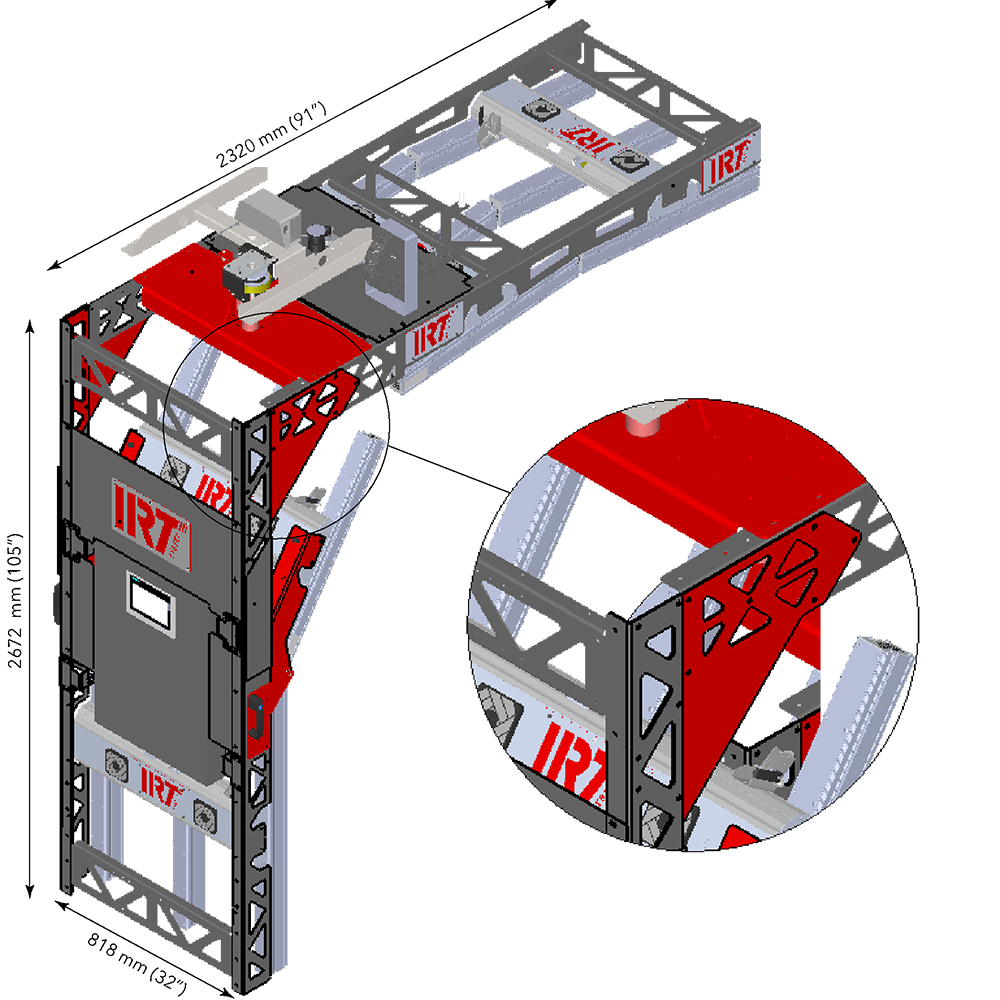

Each zone is equipped with shortwave infrared lamps, gold coated reflectors and pyrometer. 3 IR lamps/zone with a total power of 38 kW.

- Two distance sensors, top and side

- Three IR lamps per zone

- Four pyrometers – one per zone

- Speed = 20-200 cm/min

Technical Specification

IRT FlexiCure

- IRT FlexiCure

- Rated voltage

- 400-480 V ~3Ph/PE ± 5%

- Nominal frequency

- 50 - 60 Hz

- Full load current

- 55 A

- Main disconnect fuse

- 65 A

- Weight FlexiCure (excl rails)

- 150 kg

- Sound pressure level

- ≤ 70 dB (A) @ 1 m

- Sound Power level

- ≤ 70 dB (A) @ 1 m

- Curing temperature (curing surface)

- Max. 170°C

- Ambient temperature (during operation)

- Max. 40°C

Spare part list

As a Hedson Partner you can log-in to take part of our spare part lists. Log in…

If you are a Hedson Partner but don’t have access to the Partner Portal, please contact your Hedson contact person to get your account.

If you are an end-user, please contact your local reseller for more information.