curing equipment by Hedson

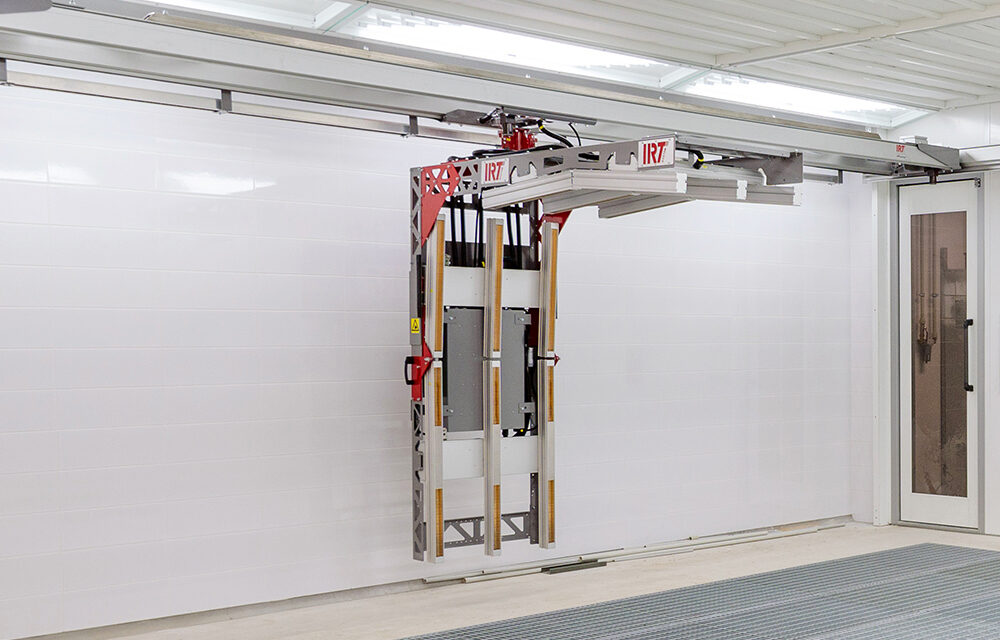

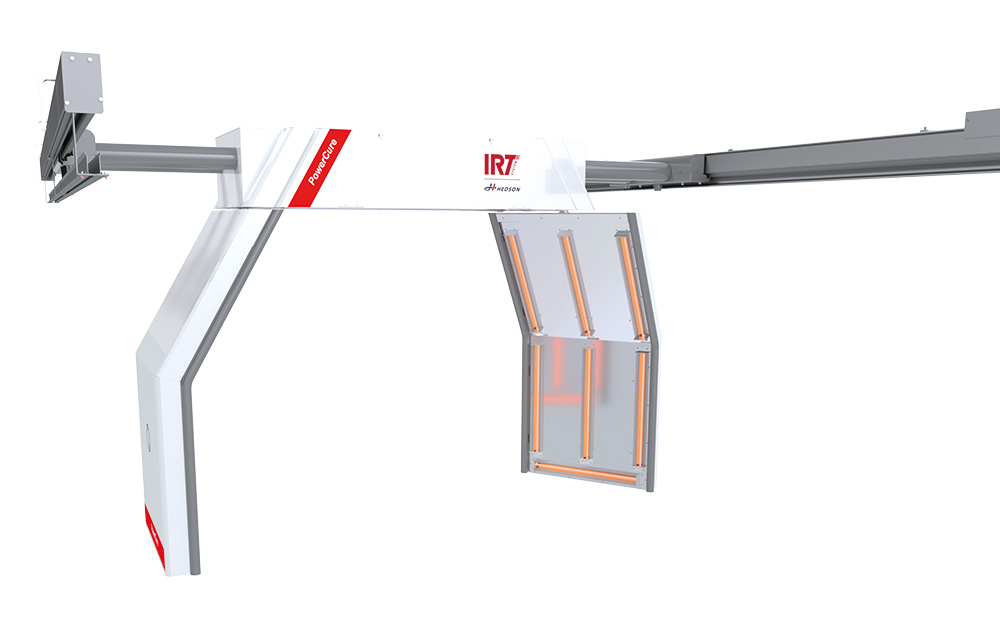

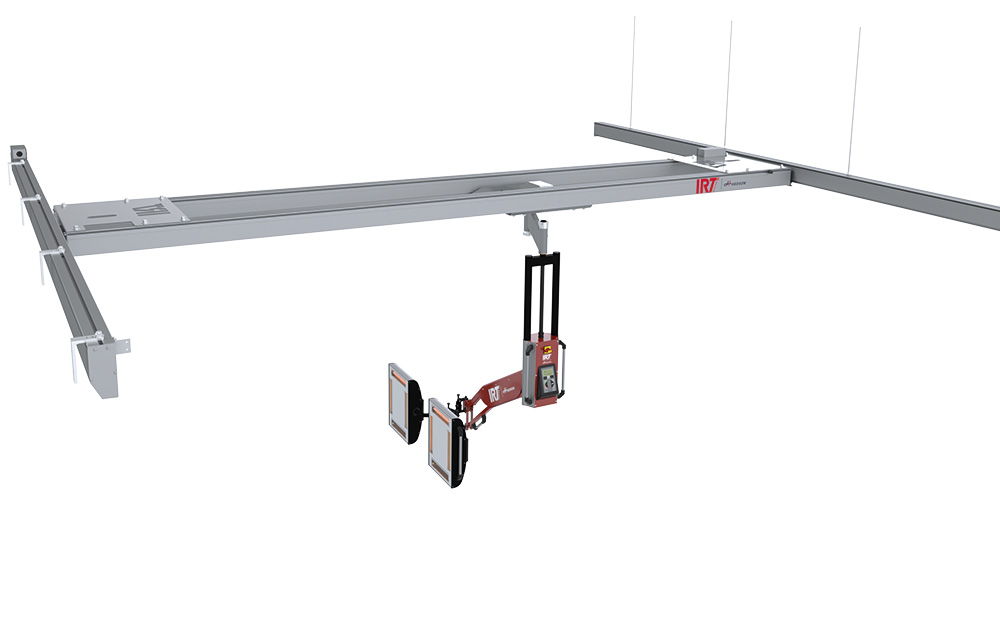

Ceiling-mounted dryers are ideal for body shop use, since they do not take up usable space and encroach into the working area

curing equipment by Hedson

Save energy consumption and make the body shop more comfortable

Curing by Hedson

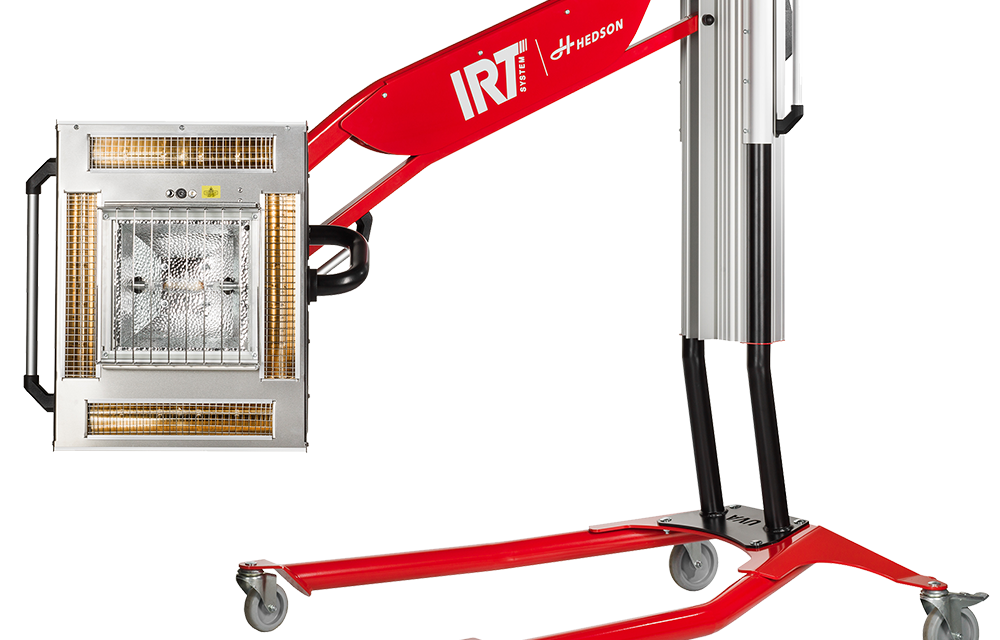

Advanced and user friendly technology

Careful consideration of body shop heating requirements will not only result in energy consumption savings but also make the body shop more comfortable. IRT by Hedson curing products ensures that they don’t take up unnecessary floor space and due to the freeform reflectors heat consumption are reduced to a minimum.

- Short curing times

- Large curing area

- Even heat distribution

- Gold-coated FreeForm reflectors

- Reduced energy consumption

- Environmentally friendly

How does the curing process work?

In order to transfer the paint pigments to the surface when painting with a spray gun, a fluid media is needed, like solvent or water. The curing process removes this fluid media from the paint. It’s a delicate process as the fluid /different solvents need to leave the paint layer in the right speed and at the right temperature.

If not, there will be problems and the paint job must be redone. Problems can occur both when the solvents leave the paint too quickly, or when the surface closes too quickly and the solvent residues are locked in in the paint layer.

A correct flash-off curing process cures the paint material so that the solvents leave the paint in the right speed and at the correct temperature.

Most of the solvents have left the paint material during the flash-off process and the curing curve has reached the maximum temperature of the specific curing. The next step in the curing process is to bake the paint until it is completely cured. Different paint materials need different curing time.

A correct full bake curing process cures the paint material so that it is completely cured. After the surface has cooled down it can be sanded or polished.

Curing products by Hedson