NEW: Infrared curing with Thermal Camera

Identify hot spots

Infrared CURING with Thermal Camera

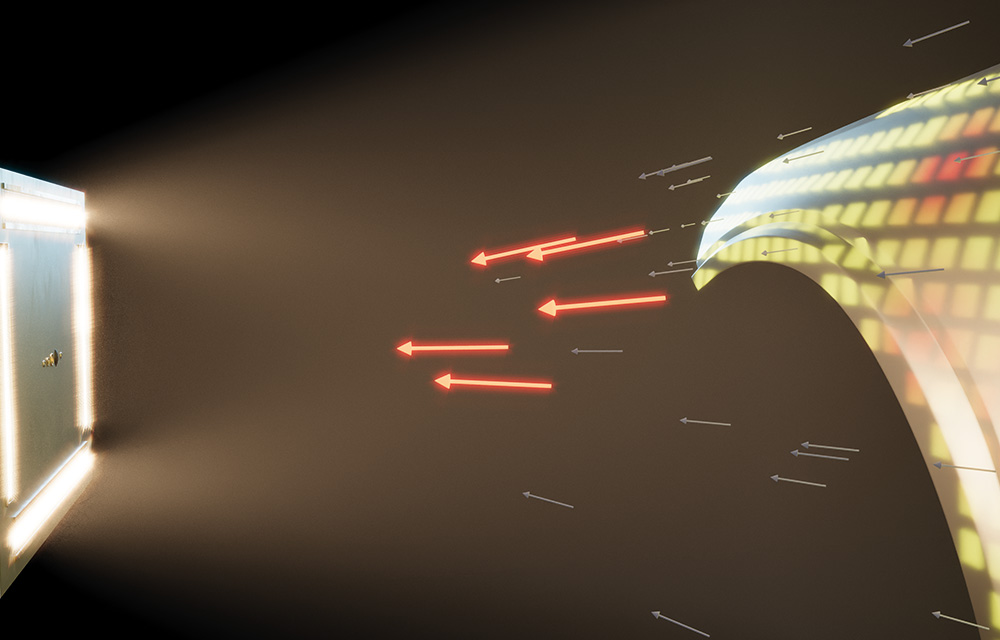

Our thermal camera acts as a “smart eye” for the curing unit – automatically adjusting the infrared lamps to achieve uniform, precise and energy-efficient curing.

Large coverage: 768 individual measuring points over 170×90 cm.

Feed back to control system: Temperature data is continously fed to the control system, which adjusts IR lamp intensity and exposure time to maintain the desired curing profile.

Result:

- Accurate, real-time temperature monitoring

- Consistent quality

- Overheating prevention

- Energy use optimization

TCR: Professional Infrared Curing controlled by Thermal Camera and Radar from IRT the curing company

Quick facts Thermal camera

Thermal camera

32×24 Array = 768 individual pyrometers.

Measuring point per pyrometer approx. 5×4 cm (at a distance of 60 cm).

Surface temperature mapping area 170×90 cm.

Continuously identifies and measures the 5 hottest target points. Delivers an average temperature value based on these.

Temperature profiles can be logged for quality assurance, traceability, and process optimization.

Radar Distance Sensor

Intelligent and exact distance measuring.

TCR: The intelligent curing station

Automatically optimizes and documents each curing job

- Touch screen for instant access

- Radar distance sensor confirms correct distance

- Time, ramp and temperature is built-in for putty, filler, base, clear, plastics

- Continuously adjusts IR power to keep the temperature on track

- Delivers only the power needed to reach the set temperature

- The real-time process is displayed, so the operator stays informed

- Tracks performance, usage and maintenance needs

Intuitive display

5” touch screen with dual navigation options: scroll or tap, whichever you prefer

Key functions are also accessible via physical buttons — ideal when working with gloves

- Highly durable, hardened glass protects the display

- Clear visibility even in brightly lit workshops

- Optimized viewing angle ensures good readability

- Withstands cleaning with both solvents and razor blad

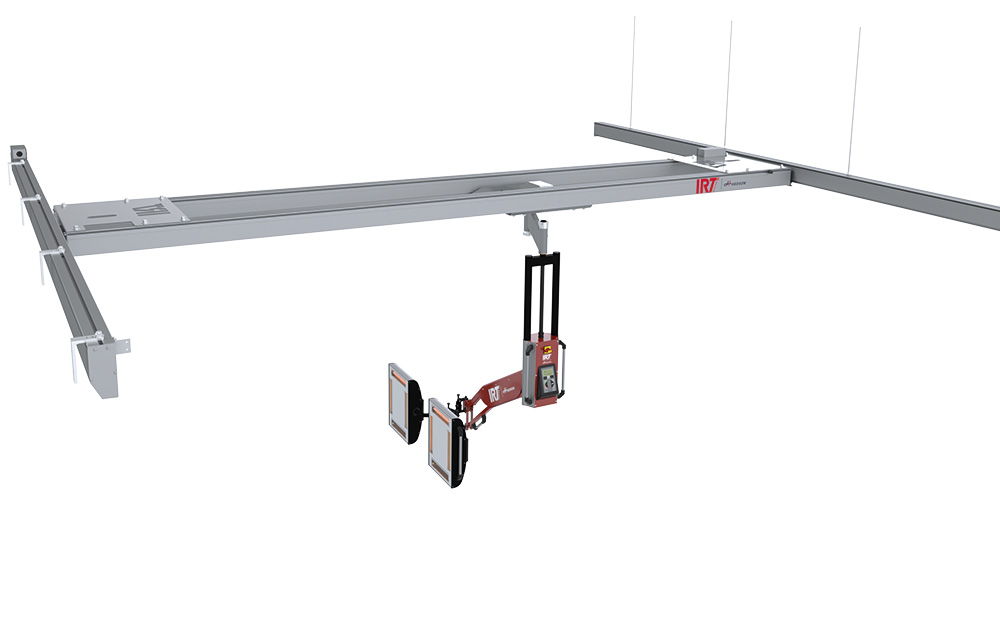

4-1 and 4-2 TCR

Finger-light arm design

Smooth height adjustment

Self-locking

Small footprint when not in use: cassettes park between the legs

Integrated cables

Precision adjustment

Perfect positioning of cassettes

Low slim base

Moves easily

Access under vehicles

Secure, tip-resistant design

Insight: Temperature control

Precision cooling for lasting performance

More than just cooling.

Adaptive fan speed provides:

- Minimized noise levels

- Enhanced protection and long-term reliability

- Extended filter life

- Reduced, unnecessary energy consumption

What is adaptive ventilation?

Adaptive ventilation continuously regulates fan speed – operating quietly under normal conditions and ramping up only when additional cooling is required. At high temperatures, the fan instantly accelerates to full speed to safeguard all system components.

Koster and Vinga, designed in-house

(Our sensor boards are traditionally named after Swedish lighthouses.) The Koster main board and Vinga sensor board are custom-designed and fully programmed in-house to manage key system functions. They include built-in overheat protection through NTC analog temperature sensors.

4 -1 TCR (1 cassette)

| Part no. | Current | Output power | Fuse | Voltage |

|---|---|---|---|---|

| 801524 | 9A | 6kW | 10A | 400V, 3 PH, 4-pin, EU |

| 801520 | 9A | 6kW | 10A | 400V, 3 PH, 5-pin, EU |

| 801522 | 15A | 6kW | 16A | 230V, 3 PH, EU |

| 801523 | 9A | 6kW | 10A | 400V, 3 PH, AUS |

| 801525 | 15A | 6kW | 16A | 200V, 3 PH, 4P, JP |

4-2 TCR (2 cassettes)

| Part no. | Current | Output power | Fuse | Voltage |

|---|---|---|---|---|

| 801504 | 16A | 12kW | 16A | 400V, 3 PH, 4-pin, EU |

| 801500 | 16A | 12kW | 16A | 400V, 3 PH, 5-pin, EU |

| 801502 | 30A | 12kW | 32A | 230V, 3 PH, EU |

| 801505 | 30A | 12kW | 32A | 200V, 3 PH, 4P, JP |

| 801503 | 16A | 12kW | 16A | 400V, 3 PH, AUS |